Network problems

Unlike production equipment where maintenance can be planned, a wireless network can be working one minute and down the next – without warning and without any indication of how to fix it. Sometimes a network failure is made worse because it is unclear who should take responsibility for restoring the network. Is it the job of the Operations Manager or IT Manager to respond to such issues?

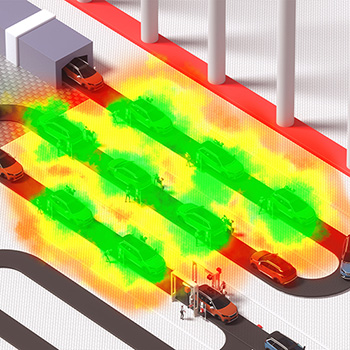

Wireless communication is a relatively new technology, so Operations Managers and Quality Teams - while highly experienced in mechanical means of production - do not always have the relevant skills to design and implement a wireless-based production network. As a result, the responsibility commonly devolves to the IT team who may understand the basic principles of wireless communication, but generally lack the specific knowledge required to apply it successfully in a manufacturing context. The same is true of external Wi-Fi suppliers: they understand how to assess a network, perform a WiFi survey and build a heat map, but lack the vital industrial expertise.

This can lead to real problems. If the chosen wireless technology is not fit for purpose, it will be inherently unreliable. So, instead of improving production, going wireless can lead to more issues than it was supposed to fix. Snagging issues can lead to delays - all of which adds cost.