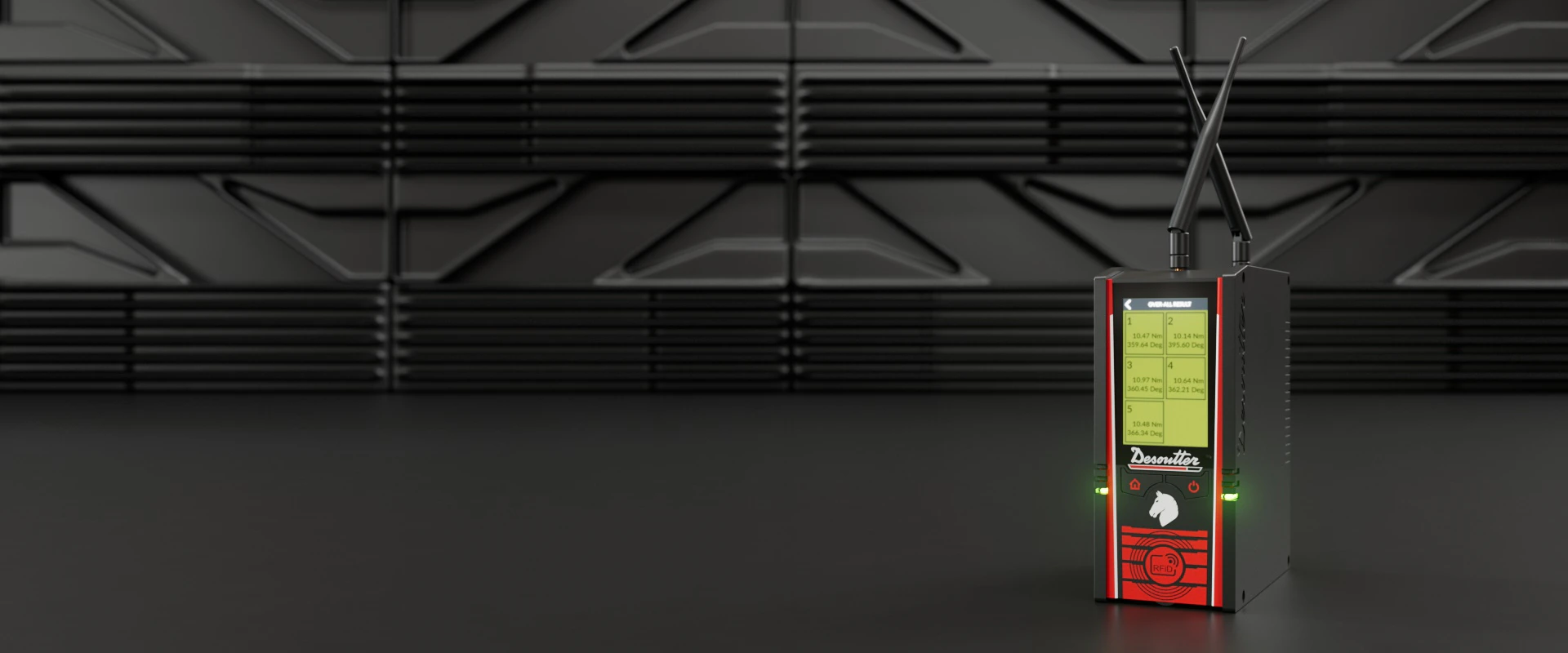

The CONNECT is an innovative industrial smart hub offers a single point of connection for communications between the factory network and up to 20 cordless tools , reducing cost of ownership and simplifying installations for easier line rebalancing. Born to answer your challenges:

Key facts about the CONNECT

Compact

Foot print optimization with only 4L

Multi-assets

Up to 20 tools, only one CONNECT

Scalability

Fine-tune the tightening units with feature management

Flexibility

Fast tool rebalancing in less than 10 seconds

Boost your flexibility

- Get what you really need with feature management

- Multi-cordless tool solution

- Single connection to plant system

- Compatible with all Desoutter wireless communication tools

Boost your uptime

- KPI-Management

- Fast tool rebalancing with easy pairing

- Fast data and settings transfer from one Connect to another one with removal back-up memory

- No risk of errors in wireless network settings due to easy pairing process

Boost your productivity

- Data integrity

- Full traceability

- Tightening process optimization (Fieldbus/protocols -tightening strategy/ assembly process…)

- Full error proofing with additional accessories

They use the CONNECT daily

At the assembly stations where we have already replaced the pneumatic and impulse screwdrivers with smart hub systems from Desoutter, the error rate has decreased significantly

Jens Weber

production engineer - Kubota Baumaschinen

Full flexibility and scalability for maximum productivity

Multi-Tool solution

Up to 20 tools connected to only one CONNECT.

Single point of connection for up to 20 tools

Only one safety power supply. Only one Ethernet/fieldbus connection Only one stand to mount the CONNECT

Footprint Optimization

With a volume of 4L, the CONNECT can be installed anywhere under any constraints

Easy line rebalancing

Pair the tool in less than 10 seconds with easy RFID pairing feature

Capacitive industrial grade touch screen

With several display options and quick response time

Fine-tunes settings & scalable solution

With feature management fine-tunes the Tihgtening Units by loading only features needed for each applications

Feature rebalancing

Easy feature rebalancing from tightening unit to another one.

Removable integrated memory

Transfer Data and settings from one CONNECT to another in a fast and effective way

Multi-Tool solution

Up to 20 tools connected to only one CONNECT.

Single point of connection for up to 20 tools

Only one safety power supply. Only one Ethernet/fieldbus connection Only one stand to mount the CONNECT

Footprint Optimization

With a volume of 4L, the CONNECT can be installed anywhere under any constraints

Easy line rebalancing

Pair the tool in less than 10 seconds with easy RFID pairing feature

Capacitive industrial grade touch screen

With several display options and quick response time

Fine-tunes settings & scalable solution

With feature management fine-tunes the Tihgtening Units by loading only features needed for each applications

Feature rebalancing

Easy feature rebalancing from tightening unit to another one.

Removable integrated memory

Transfer Data and settings from one CONNECT to another in a fast and effective way

Connected assets

View all compatible tools

Standard Pack

Each Tightening Unit activated includes a Standard package. The standard package has been built to meet with more than 80% of requirements.