UK Manufacturing Ambitions

Two in three UK manufacturing SMEs have ambitions to grow into large businesses, according to new research. If they succeed, the sector could inject £83bn into the economy over the next 10 years. This would be a major step towards increasing manufacturing’s GDP contribution from 10% to 15%, helping the UK rejoin the world’s top 10 largest industrial nations (having recently slipped to 12th).

That ambition should be celebrated. But it also raises serious questions about how exactly this growth will be delivered. It’s clear it won’t come from people-power alone, but from productivity, process control, and automation.

UK Manufacturing SMEs Can’t Rely on Hiring Alone to Scale

The UK has around 250,000 active manufacturing SMEs, most of which are micro-businesses with fewer than 10 employees. If two-thirds of them pursue growth, that’s 160,000 businesses aiming to scale. Even if each business required just two new hires to grow, that’s 320,000 additional people – in a sector already facing 55,000 unfilled vacancies.

Clearly, this growth depends on a different lever: process optimisation. Increasing efficiency, consistency and quality by reducing errors, downtime and wasted movement.

“With manufacturers already under pressure, growth doesn’t have to mean bigger factories or bigger teams. Instead, technology can help truly maximise throughput using existing infrastructure,” says Alexander Hale, Product Manager for Desoutter UK.

A Strategic Partnership Built for Real-World Automation

Beyond its legacy in precision fastening, Desoutter’s Ecosystem of smart assembly, data analytics software, visual and operator guidance, system integration, and connected assets, has been delivering results for manufacturers for many years.

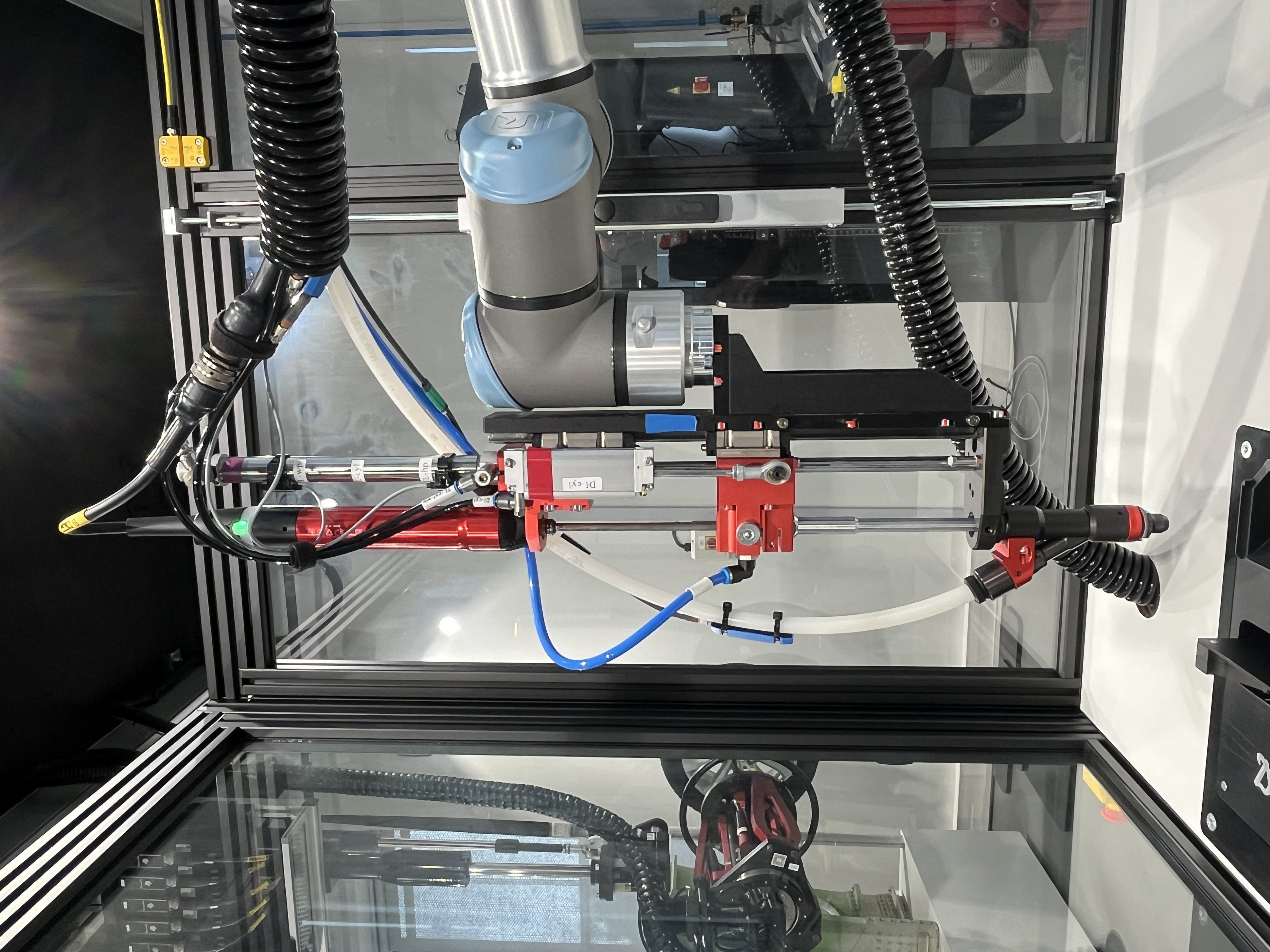

To expand its automation offering, Desoutter has globally partnered with Universal Robots (UR), pioneers of collaborative robots (cobots). UR’s user-friendly cobots integrate seamlessly into human workspaces without safety barriers, enabling automation for manufacturers of all sizes.

It’s a powerful combination that blends Desoutter’s decades of manufacturing insight and process control with UR’s flexible, user-friendly cobots. By aligning their technologies and integrating their know-how, the pair are making automation accessible to manufacturers of all sizes.

“Despite ample evidence to the contrary, there are still misconceptions that robots are costly, complicated and only suitable for high-volume factories,” says William McColl, Channel Development Manager UK&I at Universal Robots.

“The driving force behind UR was to make manufacturing easier, more flexible, and to lower the barriers around programming and company size. Partnering with Desoutter, whose equipment is already trusted across thousands of manufacturing sites and fully compatible with our cobots, simplifies automation even further. It makes everything easier for end-users and developers alike,” he continued.